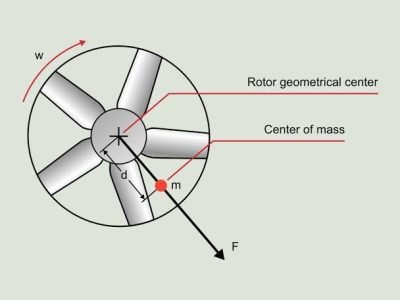

Uneven distribution of mass around an axis of rotation. A rotating mass, or rotor, is said to be out of balance when its center of mass (inertia axis) is out of alignment with the center of rotation (geometric axis).

The process of minimizing vibration, noise and bearing wear of rotating bodies by adding, removing and shifting the correction weight on rotor/fan. Unbalance problems will be rectified In-situ (On site) by our skilled and experienced ISO/ASNT Cat-II & III certified professionals to achieve maximum Machine Availability, Production & Profits to our valuable customers

The main advantage of balance “in situ” is the cost savings in the removal, transport, and assembly bench execution large rotors or weights, or installed in inaccessible locations requiring cranes or other hazardous operations.

We offer the highest Balancing Quality Grade as per ISO 21940 with precious phase measurement using the latest FFT analyzer cum field balancer & laser based optical phase reference in rotor with rigid behaviour. This system makes balancing very fast and precise positioning of balancing mass thus avoiding requirement of trim balancing.