OUR SERVICES

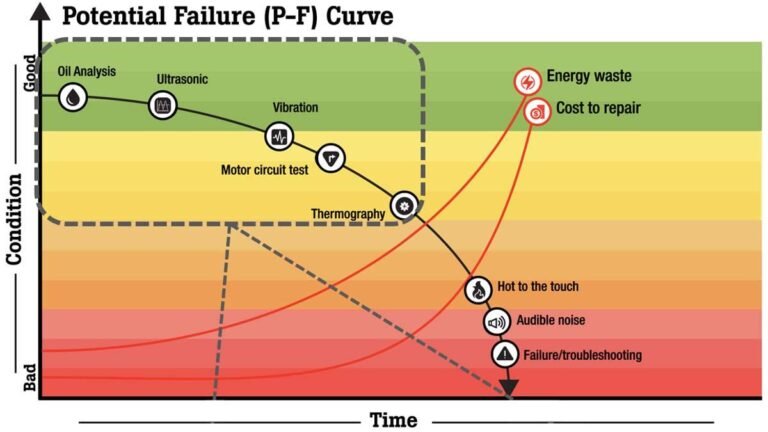

Condition Monitoring

Condition monitoring (CBM) is a maintenance approach that predicts machine health and safety through the combination of machine sensor data that measures vibration and other parameters (Online/offline) with machine vibration monitoring software. This approach enables plant maintenance engineers to on site or remotely monitor the health of each individual components of machinery and also offers a holistic, plant-wide view of mechanical operations. Condition monitoring software provide information whenever a change is detected in machine health, enabling your maintenance team to immediately assess the situation and determine if corrective action is required.

VibMaster is the one-point solution for all condition monitoring services, and by use of latest CBM technologies we are providing benefits like increased life span of machineries, Sufficient Lead time for maintenance planning, Prioritise maintenance tasks, maximum production output by high machine reliability/availability & Low inventory investment and maintenance cost to our valuable customers

VibMaster’s Condition Monitoring Services Include

- Vibration Analysis & Its Diagnostics and Prognostics

- Online Vibration Monitoring System

- Laser Shaft Alignment

- In-situ Dynamic Balancing of Rotors

- Infrared Thermography

- Ultrasound Monitoring

- Motor Current Signature analysis- MCSA

- Natural Frequency & Resonance Analysis

- Operating Deflection Shape(ODS) & Modal Analysis

- Non-Destructive Testing (NDT) Services

- Oil Analysis Services

Other Industrial Programs We Are Serving

- Implementation of Condition Monitoring Program

- Industrial trainings

- Expert Industrial Visit for CBM aspects

- Route Cause Analysis (RCA)

- Failure mode and criticality analysis (FMECA)

Industries We Serving

Power Generation

Oil & Gas

Pulp & Paper

Pharmaceutical & Biotech

Chemical Processing

Metal & Minerals

Industrial Manufacturing

Naval & Marine

Wind Power

VibMaster’s engineers are fully accredited in compliance with current Health & Safety regulations and safe-working practice. Accreditations include ISO and ASNT, and are available for inspection on request