Vibration Analysis is a predictive maintenance method which allows early problem detection in rotating machinery and prevent machine from catastrophic failure and high maintenance cost.

VibMaster having ISO/ASNT 18436-2 Cat-II & Cat-III Certified Vibration Analyst, which are very few in India – Leading the vibration analysis program and serving our valuable customer through on-site AMC’s and Call based vibration analysis services using world class measuring instruments through PAN India.

All CBM reports will be prepared and witnessed by ISO Cat II-III Vibration expert with precise maintenance assessment and proper lead time to prevent machinery from catastrophic failure. Apart from the same, all our other engineers have considerable experience in the field ensure quality analysis for our customers.

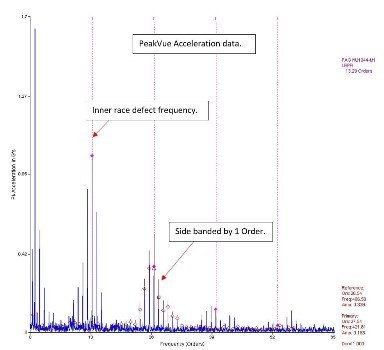

By the study of FFT Spectrum, Time Waveform and Phase Analysis we can identify below mentioned possible causes of high vibration.